Wireless Intelligent Sensor

Wireless Intelligent Sensor

Multi-condition Full-information

Multi-condition Full-information Combining a high-performance ARM processor, an FPGA logic array and DSP floating-point arithmetic, the high-speed edge computing gateway boasts superb edge computing ability.

Multi-dimensional Data Analysis and Comparison + Big Data-Based Deep Mining Technology: Accurate Machine Warning.

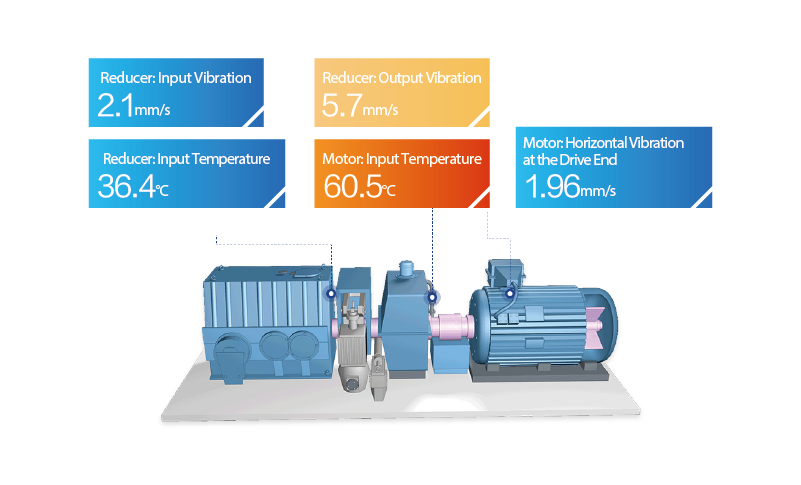

Real-time Data Monitoring + 3D Machine Model: A Full Picture of Machine Condition.

Staff Performance Appraisal: An Additional Function

Bring the Most Out of Data with the Powerful Platform Structure: An Important Asset.

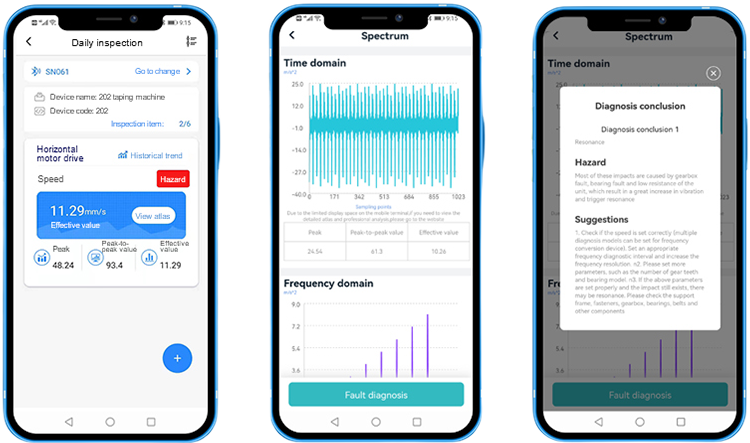

Compact and Multi-functional; Supporting Real-time Spectral Analysis and One-click Fault Analysis During Inspection.

The system analyzes the machine monitored based on detected failure signals, expertise knowledge and past facts in accordance with troubleshooting theories, and delivers fast and reliable diagnosis.

The system contains the information on 80,000+ bearings and various components such as gears and blades, and encompasses mass mechanism models applicable to all kinds of field industrial machines.

Professional Multidimensional Diagrams and Charts + Degree, Characteristic Values and Other Data + Top Expert Wisdom: Maximizing the Value of Diagrams and Charts.

Full-lifecycle data on machine operation is collected in full. Independent inventory management enables automatic warehouse-in/out of used materials during overhaul and lubrication to facilitate inventory assessment and intelligent purchase.

APP: easy preparation of work tickets and overhaul plans. Streamlined document process: higher operation and maintenance efficiency, and true, reliable and complete data.

Condition monitoring, intelligent diagnosis and machine management all in one: meet all your needs.

Data Monitoring and Machine Control Combined: A Smarter Digital Factory

A Glimpse into the Future

Cloud-based Machine for Safer Operation

2

2